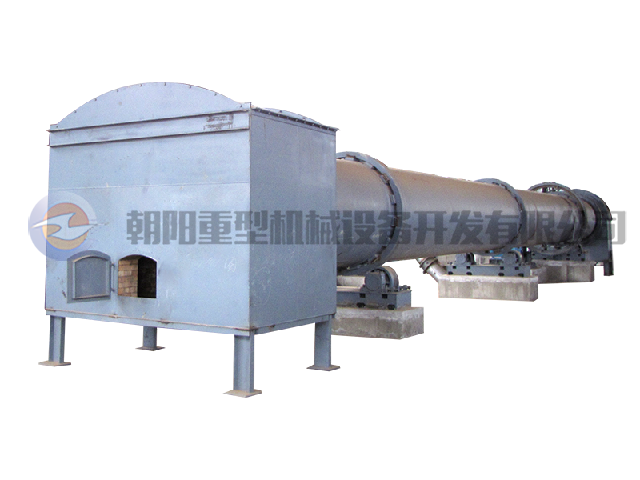

External heating rotary kiln

Category:

Rotary Kiln Equipment

产品详情

product description

In the metallurgical industry, rotary kiln can be divided into internal heating rotary kiln and external heating rotary kiln according to different heating methods. The material of the externally heated rotary kiln is not in direct contact with the flame and the flue gas. The heat source is between the heating furnace and the cylinder, and the material is heated by the heat transfer of the heat-resistant steel cylinder wall. The lining of the heating furnace is refractory fiber, which can save energy and reduce consumption. It is especially suitable when dealing with requirements such as high toxicity, high smoke concentration and high product purity.

Technical performance and characteristics

|

|

|

working principle

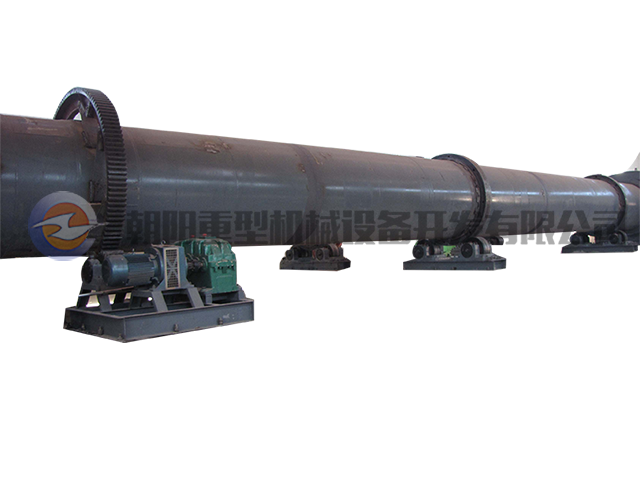

The material to be burned is uniformly fed into the kiln cylinder through the feeding mechanism of the kiln hopper. Under the driving of the transmission device, the material advances along the axial direction of the cylinder with the rotation of the cylinder, and the material is turned over to make the calcination uniform. . A heating chamber is arranged outside the cylinder. The heat generated by the calcination is transferred to the material through the cylinder, and the material is decomposed, dried, calcined and calcined at a high temperature. The calcined material is discharged through a discharge valve and used after being cooled and packaged.

Product atlas

Technical Parameters

| model | specification | Designing ability | electric motor | Reducer | weight | ||

| (t/h) | model | power(kw) | model | Speed ratio | (t) | ||

| WY118 | Φ1.18×14 | According to the material | YCT225-4A | 11 | ZS75-8-1 | 112 | 33 |

| WY65 | Φ0.65×11 | According to the material | YCT200-4B | 7.5 | ZS65-8-1 | 112 | 25.3 |

| WY40 | Φ0.4×4.8 | According to the material | YCT200-4A | 5.5 | ZS50-7-1 | 100 | 16 |

| WY120 | Φ1.2×20 | According to the material | YCT225-4A | 11 | ZS75-8-1 | 112 | 48 |

| WY150 | Φ1.5×28 | According to the material | YCT225-4B | 15 | ZS95-9-1 | 125 | 68 |

Keyword:

合作案例

Message