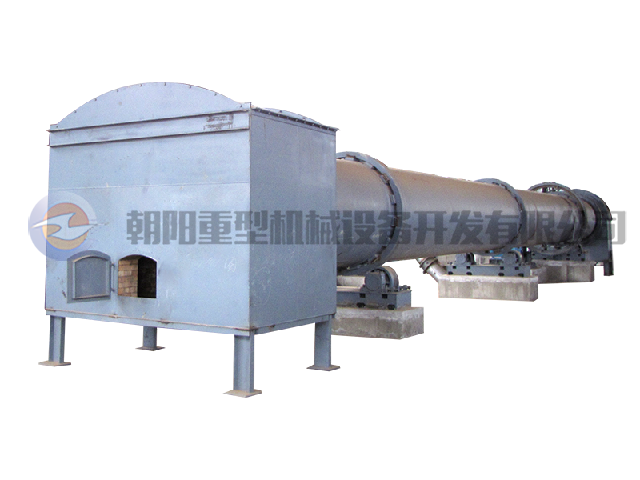

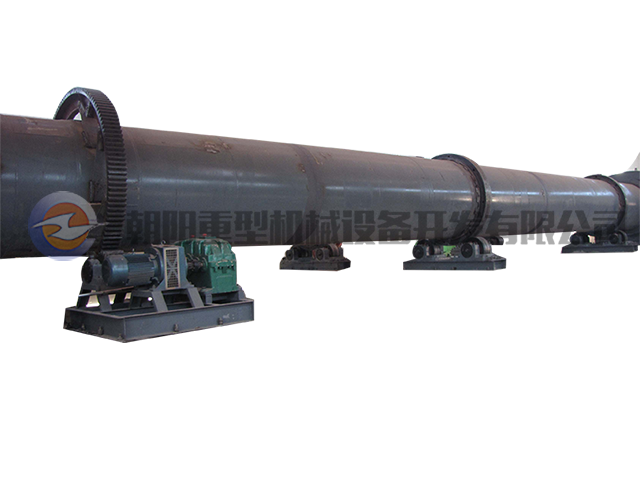

Active lime rotary kiln

Category:

Rotary Kiln Equipment

产品详情

product description

Fuel economy, environmental protection and energy conservation are the main combustion principles of the new technology active lime kiln. The soil kiln has serious environmental pollution, the working environment is extremely harsh, and the work intensity is large. The new technology active lime rotary kiln solves this problem. The amount of fuel used is related to the calorific value of its furnace type and fuel. The heat required for calcining lime is derived from the combustion of fuel. The fuel and limestone are simultaneously distributed into the kiln, and different furnace types and different heating methods are used. , determines the calcination effect of the lime kiln.

Technical performance and characteristics

|

Smooth operation, reasonable structure |

working principle

The main component of limestone is calcium carbonate, and the lime component is mainly calcium oxide. After the preheater is preheated, the limestone begins to decompose at 850 ℃. From the kiln tail (the high end of the cylinder) into the kiln to 1200 ℃ to complete the calcination, due to the tilting and slow rotation of the cylinder, it is tumbling in the circumferential direction. The axial direction (from the high end to the low end) is broken down into CaO and CO2 by sintering in the rotary kiln. Different kiln shapes have different preheating, calcination, cooling and unloading methods.

Product atlas

Technical Parameters

| Product specifications | Yield | product | Effective volume | Combustion temperature | Remarks |

| (m) | (t/d) | (m³) | (℃) | ||

| Φ2.5×40 | 150 | Active lime light burnt dolomite | 142 | 1350/1250 | |

| Φ2.8×42 | 200 | Active lime light burnt dolomite | 190 | 1350/1250 | |

| Φ3.0×46 | 250 | Active lime light burnt dolomite | 235 | 1350/1250 | |

| Φ3.2×50 | 300 | Active lime light burnt dolomite | 292 | 1350/1250 | |

| Φ3.5×54 | 350 | Active lime | 390 | 1350 | |

| Φ3.6×50 | 400 | Active lime | 430 | 1350 | |

| Φ3.8×58 | 500 | Active lime | 505 | 1350 | |

| Φ4.0×60 | 600 | Active lime | 548 | 1350 | |

| Φ4.2×50 | 750 | Active lime | 670 | 1350 | |

| Φ4.3×58 | 800 | Active lime | 738 | 1350 | |

| Φ4.3×64 | 1000 | Active lime | 1005 | 1350 |

Keyword:

合作案例

Message