Electrostatic precipitators

Category:

Dust Removal Equipment

产品详情

product description

The performance of electrostatic precipitators is affected by three factors: dust properties, equipment construction and flue gas flow rate. The specific resistance of dust is an indicator for evaluating conductivity, which has a direct impact on dust removal efficiency. The specific resistance is too low, and it is difficult for the dust particles to remain on the dust collecting electrode, causing it to return to the airflow. If the specific resistance is too high, the dust particles reaching the dust collecting electrode are not easily released, and a voltage gradient is formed between the dust layers to cause local breakdown and discharge. These conditions will cause the dust removal efficiency to drop.

Technical performance and characteristics

|

|

|

working principle

The working principle of the electric precipitator is to form an electrostatic field by using a DC high-voltage power source to ionize the passing gas, and generate a large amount of positive and negative ions. Under the action of the electric field force, the positive and negative ions collide with the dust particles of the dusty gas and electrify it. Finally, it is adsorbed on the plate and then collected by vibrating.

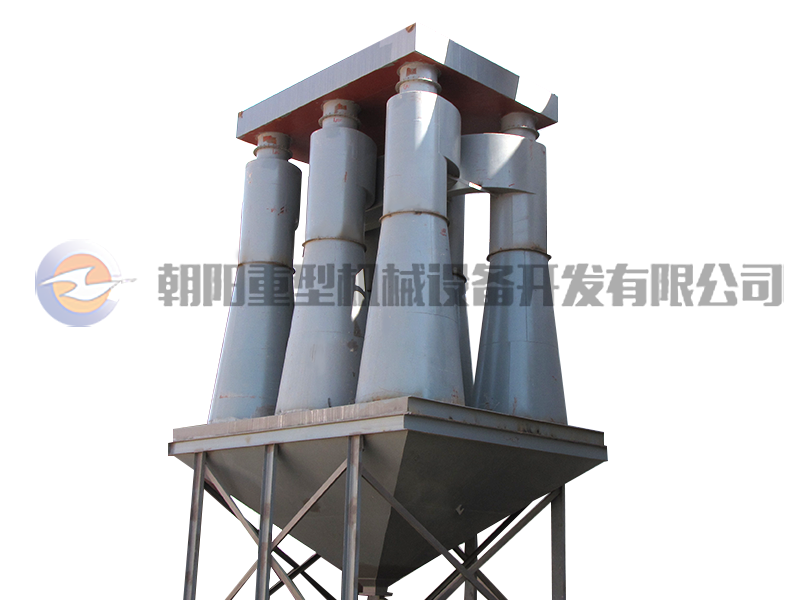

Product atlas

Technical Parameters

| Specification model | CYEP-3 | CYEP-5 | CYEP-10 | CYEP-12 | CYEP-15 | CYEP-20 | CYEP-30 |

| Nominal circulation area m2 | 3 | 5 | 10 | 12 | 15 | 20 | 30 |

| Handling the amount of smoke m3/h | 7020-11880 | 11770-19800 | 23400-39600 | 28080-47520 | 35100-59400 | 50400-86400 | 75600-129600 |

| Operating temperature ℃ | Above 20 ℃ above the dew point temperature | Above 20 ℃ above the dew point temperature | Above 20 ℃ above the dew point temperature | Above 20 ℃ above the dew point temperature | Above 20 ℃ above the dew point temperature | Above 20 ℃ above the dew point temperature | Above 20 ℃ above the dew point temperature |

| Inlet dust concentration g/m2 | ≤80 | ≤80 | ≤80 | ≤80 | ≤80 | ≤80 | ≤80 |

| Export dust concentration mg/m2 | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 |

| Dust collecting pole form | 480C template | 480C template | 480C template | 480C template | 480C template | 480C template | 480C template |

| Discharge form | BS Cathode line | BS Cathode line | BS Cathode line | BS Cathode line | BS Cathode line | BS Cathode line | BS Cathode line |

| Motor speed m/s | 0.65-1.1 | 0.65-1.1 | 0.65-1.1 | 0.65-1.1 | 0.65-1.1 | 0.65-1.1 | 0.65-1.1 |

Keyword:

prev

next

prev

next

Message