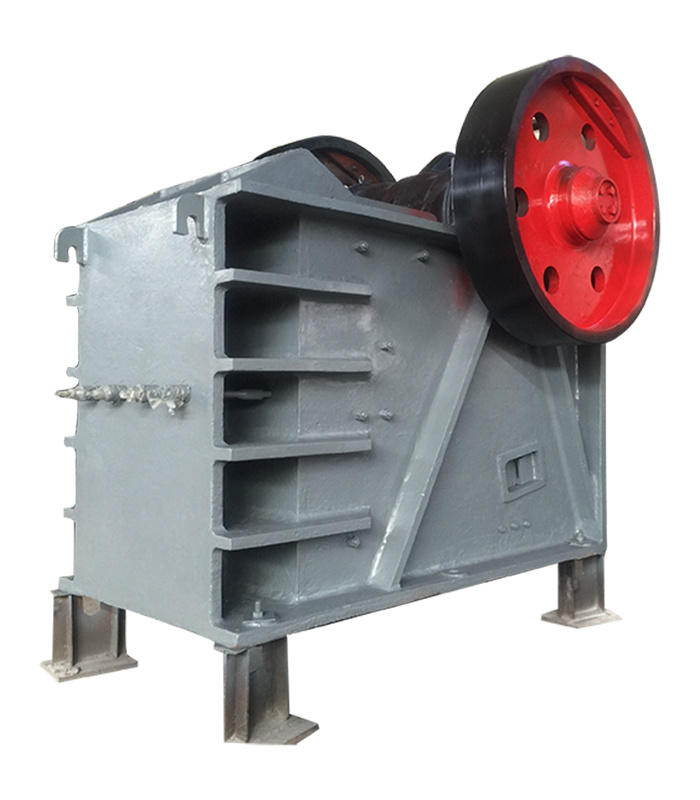

Jaw Crusher

Category:

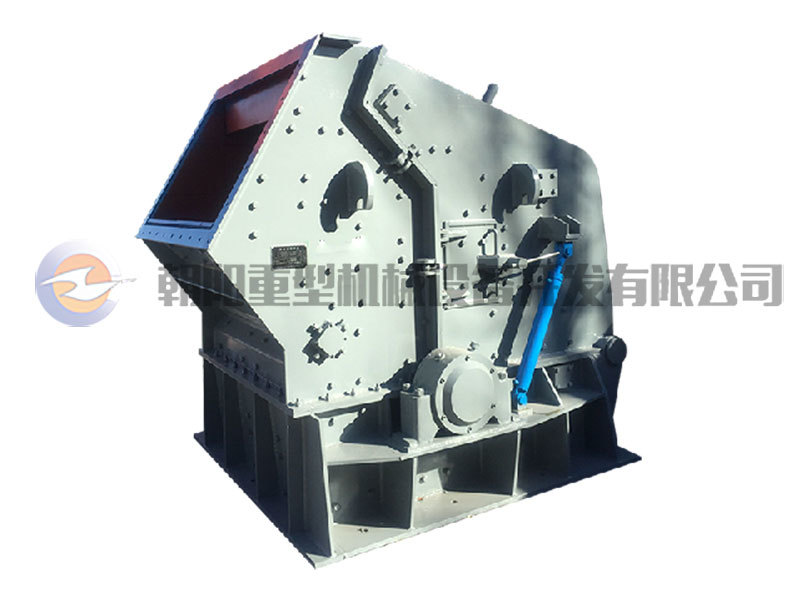

Crushing Equipment

产品详情

product description

Jaw Crusher is the first choice for material crushing in mining, building materials, chemical, metallurgical and other industries. It improves the crushing efficiency of jaw crusher in the structure of the original equipment, increases the height of the crushing chamber, and increases the production capacity; Drainage port, increase the crushing ratio; increase the swing speed of the moving shovel to improve equipment production capacity and improve product quality.

Technical performance and characteristics

|

|

Large crushing ratio The crushing ratio is large, the product granularity is uniform; the lubrication system is safe and reliable, the parts are replaced easily, the maintenance workload is small; the discharge opening adjustment range is large, which can meet the requirements of different users. |

working principle

The material is broken by the periodic motion of the moving jaw, and the material between the two jaws is crushed, split and bent during the process of swinging the axially fixed suspension. The pressure is small, the volume of the material is reduced, and the materials are close to each other and squeezed; when the pressure rises beyond the strength that the material can withstand, the crushing occurs. Conversely, when the moving jaw moves away from the fixed direction, the opposite direction is swung. The material moves downwards by its own weight. Each periodic movement of the moving jaw causes the material to be crushed once and sent a distance downward. After several cycles, the broken material is discharged from the discharge port. As the motor rotates continuously The crushing maneuvering cycle motion crushes and excretes materials to achieve mass production.

Product atlas

|

|

|

Technical Parameters

| Serial number | model | Feed port size(mm) | Maximum feed size(mm) | Discharge port adjustment range(mm) | Processing capacity(t/h) | Motor Power(KW) | total weight(T) |

| 1 | PE-150×250 | 150×250 | 125 | 10-40 | 0.6-3 | 5.5 | 1.1 |

| 2 | PE-250×400 | 250×400 | 210 | 20-60 | 8-30 | 15 | 2.8 |

| 3 | PE-320×500 | 320×500 | 270 | 30-90 | 12-50 | 22 | 4.7 |

| 4 | PE-400×600 | 400×600 | 340 | 40-120 | 17-80 | 30 | 6.5 |

| 5 | PE-500×750 | 500×750 | 430 | 50-130 | 45-130 | 55 | 12 |

| 6 | PE-600×900 | 600×900 | 500 | 65-80 | 60-200 | 75 | 17 |

| 7 | PE-750×1060 | 750×1060 | 630 | 80-200 | 90-260 | 90 | 24 |

| 8 | PE-750×1300 | 750×1300 | 80-200 | 100-300 | 130 | 31 | |

| 9 | PE-800×1100 | 800×1100 | 680 | 90-210 | 120-280 | 110 | 35 |

| 10 | PE-870×1060 | 870×1060 | 660 | 200-260 | 290-336 | 110 | 31.5 |

| 11 | PE-900×1060 | 900×1060 | 685 | 230-290 | 160-400 | 110 | 33 |

| 12 | PE-900×1200 | 900×1200 | 750 | 95-220 | 150-320 | 110 | 52 |

| 13 | PE-1000×1200 | 1000×1200 | 850 | 150-265 | 210-500 | 110 | 62 |

| 14 | PE-1200×1500 | 1200×1500 | 1040 | 150-300 | 280-500 | 180 | 100.9 |

| 15 | PEX-100×600 | 100×600 | 80 | 7-21 | 2-8 | 7.5 | 1.2 |

| 16 | PEX-150×750 | 150×750 | 120 | 10-40 | 8-35 | 15 | 4 |

| 17 | PEX-250×750 | 250×750 | 210 | 15-60 | 15-45 | 30 | 5.5 |

| 18 | PEX-250×1000 | 250×1000 | 210 | 25-60 | 16-55 | 37 | 7 |

| 19 | PEX-250×1200 | 250×1200 | 210 | 25-60 | 22-65 | 45 | 9.1 |

| 20 | PEX-250×1300 | 250×1300 | 210 | 20-80 | 20-85 | 45 | 11.5 |

| 21 | PEX-300×1300 | 300×1300 | 250 | 20-90 | 30-100 | 75 | 13 |

| 22 | PEX-300×1200 | 300×1200 | 250 | 20-90 | 25-80 | 75 | 12 |

Keyword:

合作案例

Message