Pulse bag filter

Category:

Dust Removal Equipment

产品详情

product description

The pulse bag filter is a new high-efficiency pulse bag filter that is improved on the structure and pulse valve by using the high-efficiency pulse injection technology on the basis of the bag filter. It solves the problem of low pressure in the open air and compressed air source. And the way of cleaning is completely changed.

Technical performance and characteristics

|

|

|

working principle

The bag type dust collector drives the dust-containing gas into the dust chamber inside the dust collector by the dust collecting fan. After the air passes through the filter bag, the air is cleaned and discharged by the dust collecting fan, and the dust is prevented from being adsorbed on the outer surface of the filter bag, and then The pulse valve controls the injection of high-pressure gas into the inside of the filter bag, and the dust is shaken off and enters the collecting hopper. After the wind-locking device is installed (there are two types of air-locking devices: a star-shaped unloading device and a flapping valve. According to the specific use environment, it is discharged.

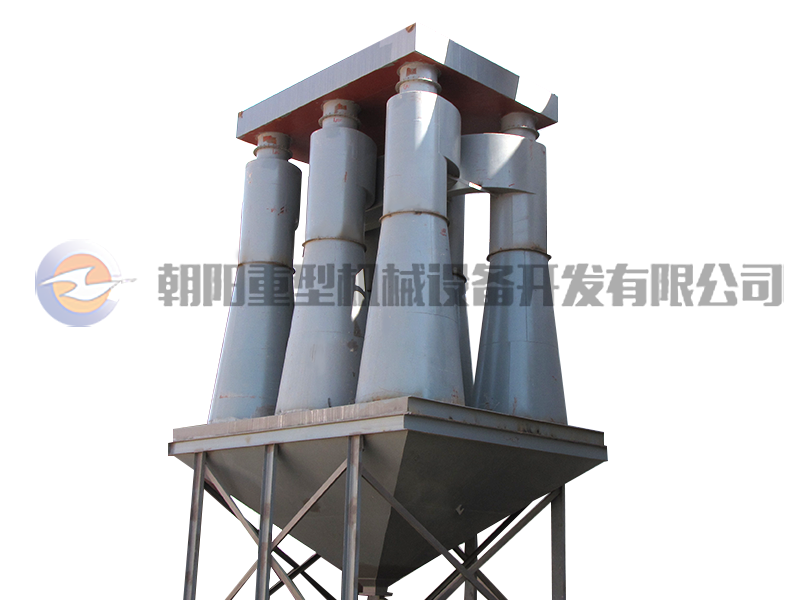

Product atlas

Technical Parameters

| Parameter technology model | PPCS32- | PPCS64- | |||||||

| 3 | 4 | 5 | 6 | 4 | 5 | 6 | 7 | 8 | |

| Handling air volume(m3 /h ) | 6900 | 8930 | 11160 | 13390 | 17800 | 22300 | 26700 | 31200 | 35700 |

| Filtering wind speed(m/min) | 1.2 | ||||||||

| Total filtration area(㎡) | 93 | 124 | 155 | 186 | 248 | 310 | 372 | 434 | 496 |

| Net filtration area(㎡) | 62 | 93 | 124 | 155 | 186 | 248 | 310 | 272 | 434 |

| Number of dust collectors | 3 | 4 | 5 | 6 | 4 | 5 | 6 | 7 | 8 |

| Total number of filter bags | 96 | 128 | 160 | 192 | 256 | 320 | 384 | 448 | 512 |

| Dust collector resistance(Pa) | 1470—1770 | ||||||||

| Imported gas dust concentration(g/m3 ) | <200 | <1000 | |||||||

| Export gas dust concentration(g/m3) | <0.1 | ||||||||

| The dust collector housing is subjected to negative pressure(Pa) | 5000 | ||||||||

Keyword:

Message