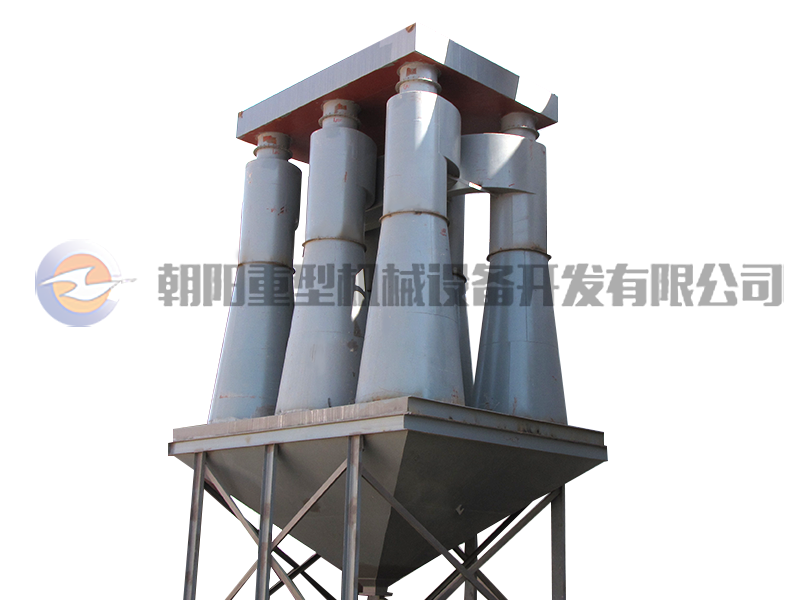

Micro-powered dust collector

Category:

Dust Removal Equipment

产品详情

product description

Micro-powered dust collector is a special dust collection series for conveying equipment. It is suitable for dust collection of dusty gas with high concentration. Gas dust concentration is up to 1000g/m2 (standard) or above. It is also suitable for cement industry, metallurgy, chemical industry, Dust collection from exhaust gases such as machinery and civil boilers. The micro-powered dust collector filter can withstand normal temperature operation or work in an environment where the temperature is not higher than 80 degrees Celsius.

Technical performance and characteristics

|

|

|

working principle

The non-powered dust removal technology uses the aerodynamic principle to create a closed-loop flow of airflow in the precipitator by utilizing the pressure difference generated when the material falls, and disperse and dust the dust points. On the equipment to be dusted, a dust chamber is installed, and a stress plate is placed in the dust chamber. When the material is dropped or subjected to vibration, the dusty airflow moves upwards, hits the stress plate, becomes turbulent, the velocity and direction of the airflow change, and the dust of the large particles settles. In the sealed dust chamber, the belt continues to run. The micro-negative pressure is generated at the material discharge port, and a sealed gas return pipe is arranged in the dust-removing chamber, and the micro-positive pressure air flow is led to the material discharge port to maintain the pressure balance, and the closed-loop circulation in the dust collector is realized to ensure the continuous sedimentation of the dust.

Product atlas

Technical Parameters

| model Main technical performance |

WDLCC50 | WDLCC60 | WDLCC80 | WDLCC90 |

| Handling air volume(m³/h) | 4000-4300 | 6000-7000 | 8500-9000 | 10800-13000 |

| Filtering wind speed(m/min) | 0.9—1.0 | 1.2—1.5 | 1.2—1.5 | 1.2—1.25 |

| Inlet temperature(°) | <120 | <120 | <120 | <120 |

| The housing is subjected to negative pressure(Pa) | 5000 | 5000 | 5000 | 5000 |

| Number of rooms(a) | 1 | 1 | 1 | 1 |

| Filter cartridge | 24 | 28 | 40 | 50 |

| Total filtration area(m²) | 72 | 84 | 120 | 150 |

Keyword:

prev

next

prev

next

Message