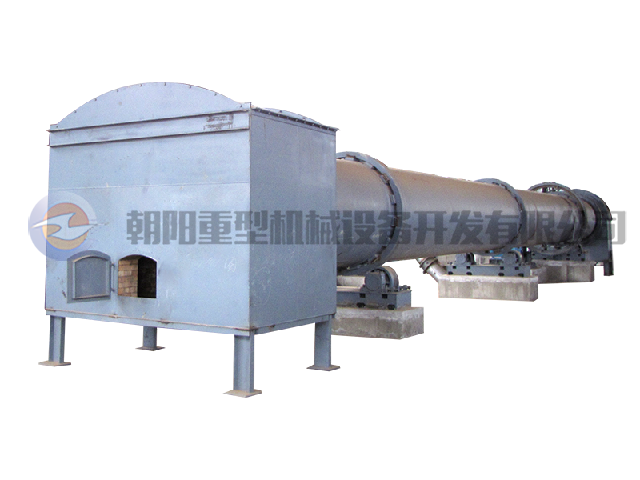

Molybdenum iron smelting rotary kiln

Category:

Rotary Kiln Equipment

产品详情

product description

The main function of oxidizing roasting of molybdenum concentrate is desulfurization, which is an exothermic reaction process. According to this principle, our company has developed a self-heating sulphide ore roasting rotary kiln for roasting molybdenum concentrate due to the heat supplied during roasting. The air is sufficient, so the oxidation process is accelerated, the equipment capacity is increased, and the product quality is good. The MoO3 in the calcining can reach more than 80%, which makes the smelting effect of ferromolybdenum better.

Technical performance and characteristics

|

|

|

|||||

|

|

|

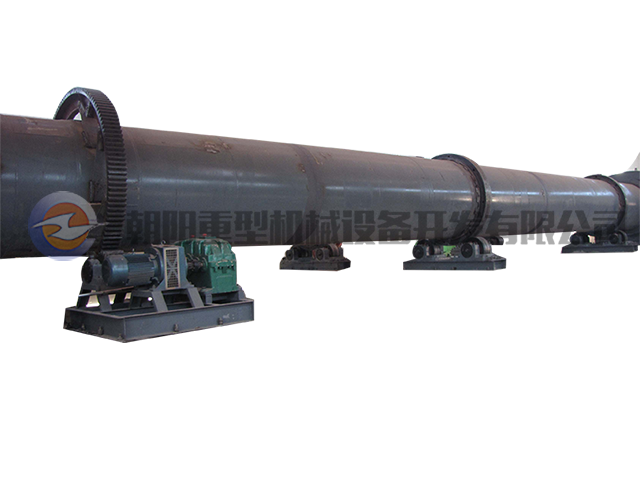

working principle

A heat exchanger is arranged in the rotary kiln to ignite the molybdenum concentrate to establish a calcination temperature zone, and the heat released during the roasting process is replaced with a portion of the heat by the air, and the recovered hot air is re-reasonable by the heat exchange device. It is input into the roasting rotary kiln to keep the molybdenum concentrate in the kiln kept roasting. Under this working condition, no external heating source is needed to achieve the self-heating roasting of molybdenum concentrate, and the external heating energy consumption approaches zero and the CO2 emission approaches zero.

Product atlas

Technical Parameters

| model | specification | Designing ability | electric motor | Reducer | weight | ||

| (t/h) | model | power(kw) | model | Speed ratio | (t) | ||

| WY118 | Φ1.18×14 | According to the material | YCT225-4A | 11 | ZS75-8-1 | 112 | 33 |

| WY65 | Φ0.65×11 | According to the material | YCT200-4B | 7.5 | ZS65-8-1 | 112 | 25.3 |

| WY40 | Φ0.4×4.8 | According to the material | YCT200-4A | 5.5 | ZS50-7-1 | 100 | 16 |

| NY25 | Φ2.5×40 | 3-6 | YCT250-4A | 55 | ZS125 | 63.1 | 145 |

| NY26 | Φ2.6×40 | 10 | YCT250-4A | 75 | ZS145 | 49.63 | 165 |

| NY28 | Φ2.8×44 | 15 | YCT250-4A | 55 | ZS145 | 49.63 | 195 |

Keyword:

prev

prev

合作案例

Message