Raymond Mill

Category:

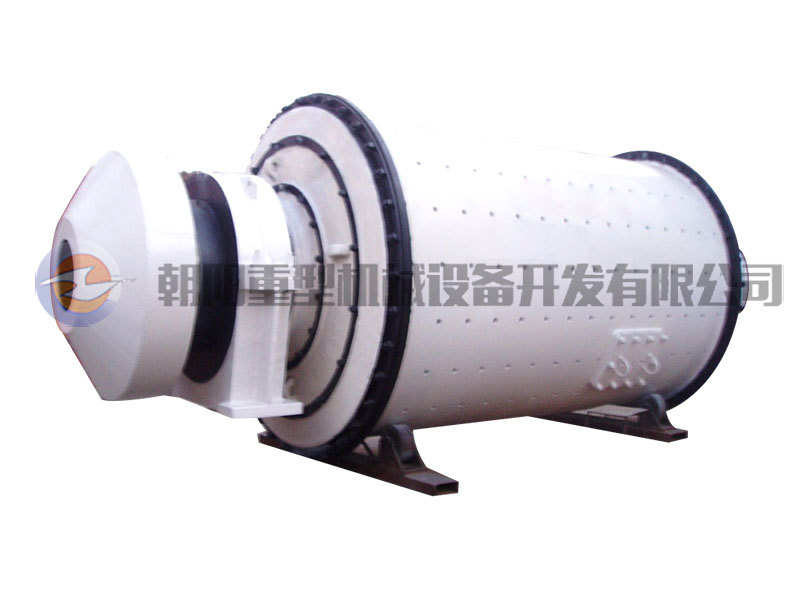

Ball Mill

产品详情

product description

Raymond Mill is a high-fine powder equipment suitable for high-efficiency closed-circuit circulation in mining, chemical, building materials, refractory materials, metallurgy and other industries. Raymond mill is widely used in barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, glass. High-fine powder processing of more than 280 kinds of materials, such as non-flammable and explosive ore, chemical, building materials and other industries with a Mohs hardness of not more than 7 grades and a humidity of 6% or less. The finished product has a particle size of 50-325 mesh. Arbitrarily adjusted, some materials can be as fine as 600 mesh.

Technical performance and characteristics

|

|

|

working principle

After the Raymond mill crushes the bulk material to the required feed size, the bucket elevator transports the material to the storage bin, which is then sent by the electromagnetic feeder to the grinding chamber of the main machine to enter the grinding chamber. The material in the grinding is ground between the grinding roller and the grinding ring. The powder after grinding is brought to the analysis machine by the fan airflow. The fine powder that meets the fineness is sent to the large cyclone collector through the airflow for separation and collection. And then discharged through the unloader is the finished product.

Product atlas

Technical Parameters

| Model parameter | 3R1410 | 3R2115 | 3R2615 | 3R2715 | 4R2715 | 4R3016 | 4R3216 | 5R4119 |

| Maximum feed size(mm) | 5-8 | 15 | 20 | 20 | 15-25 | 15-25 | 25 | 30 |

| Finished product size(mm) | 80-325 | 80-325 | 80-325 | 80-325 | 80-325 | 80-325 | 80-325 | 80-325 |

| Class production(different materials) | 1-10 | 1-18 | 2-25 | 2-28 | 3-30 | 3-36 | 3-38 | 3-45 |

| Center shaft speed(r/min) | 240 | 180 | 160 | 160 | 160 | 150 | 140 | 105 |

| Grinding ring inner diameter(mm) | 435 | 630 | 780 | 820 | 820 | 890 | 970 | 1280 |

| Roll diameter(mm) | 140 | 210 | 260 | 270 | 270 | 300 | 320 | 410 |

| Grinding roller and grinding ring height | 100 | 150 | 150 | 150 | 150 | 160 | 160 | 190 |

| Host(kw) | 7.5 | 15 | 18.5 | 22 | 22 | 30 | 37 | 75 |

| Fan(kw) | 5.5 | 11 | 15 | 18.5 | 18.5 | 22 | 37 | 55 |

| Analytical machine(kw) | 1.1 | 1.5 | 2.2 | 2.2 | 2.2 | 3 | 5.5 | 7.5 |

Keyword:

prev

next

prev

next

合作案例

undefined

Message