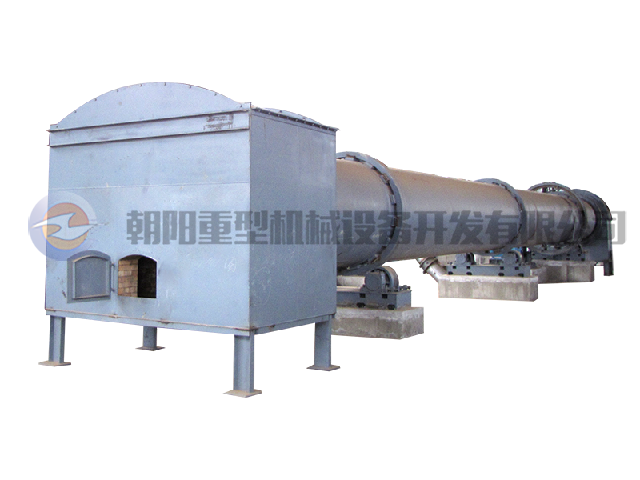

Energy-saving rotary kiln

Category:

Rotary Kiln Equipment

产品详情

product description

The energy-saving rotary kiln is characterized by the ability to perform an autothermal reaction during the roasting of the sulfide ore. The heat released by the roasting can fully satisfy the heat required for the next process and does not generate a large amount of flue gas. Based on the experiment of oxidizing roasting mechanism of sulfide ore, we proposed an optimal design scheme for the internal heating rotary kiln, which adopted a number of patented technologies, increased the kiln heat exchange air supply device, the cylinder expansion device, and adopted a novel slip ring. Structural design of power supply devices. It has high performance, high efficiency, zero energy consumption and other performance advantages unmatched by ordinary rotary kiln.

Technical performance and characteristics

|

|

|

|||||

|

|

|

working principle

The purpose of oxidizing roasting of molybdenum concentrate is to separate molybdenum from sulfur in molybdenum disulfide and convert MoS2 into MoO2 or MoO3 at high temperature. The roasting of molybdenum concentrate is a significant exothermic reaction and can be self-heating. The calcination process does not require the consumption of thermal energy and should not produce a large amount of flue gas. The principle of energy-saving rotary kiln is to use the molybdenum concentrate roasting reaction to exotherm heat recovery and maintain the self-heating reaction (no external heating source is required). The thermodynamic trend and heat balance potential of molybdenum concentrate roasting are very obvious, and the heat released by molybdenum concentrate oxidation is added. Fully recycled, it is possible to achieve zero thermal energy roasting.

Product atlas

Technical Parameters

| Serial number | structure size | Yield t/d | Recovery rate % | Residual sulfur % | Molybdenum | power kw | Fuel consumption kgce/t | Remarks |

| 1 | φ1.8x28 | 8-10 | ≥98 | 0.04-0.07 | 22 | 0 | Metallurgical | |

| 2 | φ1.8x28 | 6-8 | ≥98 | ≤2.0 | >98% | 22 | 50-100 | Molybdenum chemical |

| 3 | φ2.5/2.0x35 | 16-18 | ≥98 | 0.04-0.07 | 15x2 | 0 | Two-stage kiln | |

| 4 | φ2.5/2.0x35 | 12-16 | ≥98 | ≤2.0 | >98% | 15x2 | 50-100 | Two-stage kiln |

Keyword:

合作案例

Message