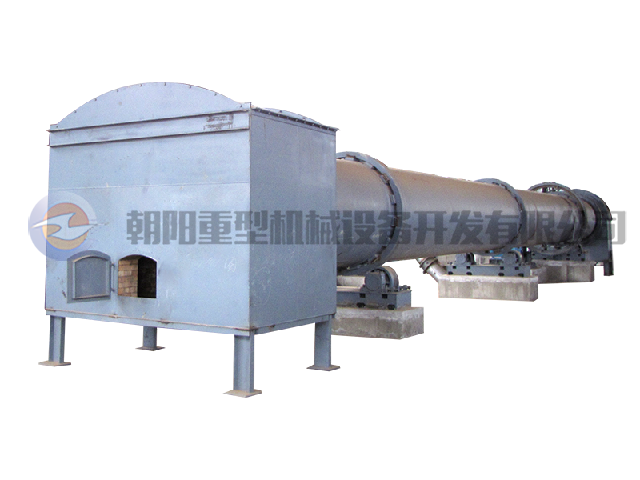

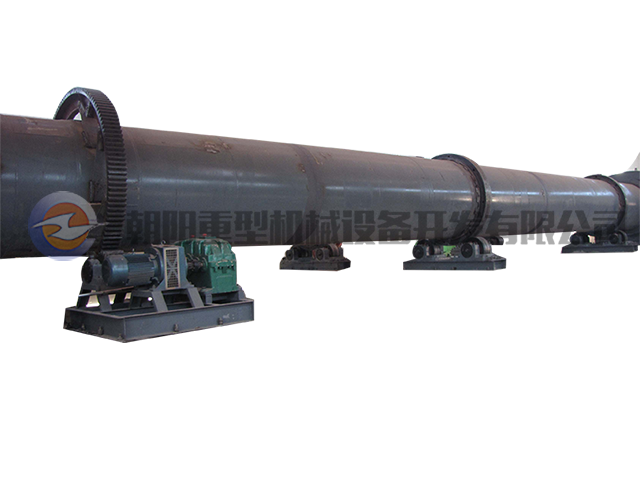

Titanium iron smelting rotary kiln

Category:

Rotary Kiln Equipment

产品详情

product description

The process of directly reducing ilmenite in a rotary kiln refers to feeding qualified raw materials such as ilmenite to a rotary kiln. In the rotary kiln, the generated high-temperature flue gas forms a countercurrent motion with the material, and the charge is heated to 900-1050 ° C. Up to 1150 ° C, the ilmenite is reduced to a high grade titanium-rich material. We added the temperature measurement and automatic adjustment control system of the rotary kiln on the original basis to ensure the quality of the calcined product. In addition, a special cylinder insulation device is used to ensure efficient use of heat.

Technical performance and characteristics

|

|

|

working principle

The rotary kiln direct reduction method is the main method for coal-based direct reduction industrial production. The process of directly reducing ilmenite in coal-based rotary kiln refers to sending qualified ilmenite raw materials and partially reduced coal to the workshop daily silo, according to After a certain proportion of ingredients, the belt conveyor is sent to the kiln end feeding end, and is fed into the kiln through the feeding tube. The rotary kiln has an inclination of 2.5-3°, and the loaded charge is slowly moved toward the discharge end by the rotary motion and the inclination of the rotary kiln. The burning coal and part of the reduced coal are injected from the discharge end of the kiln head and burned with a certain amount of primary air to generate high temperature flue gas. The flue gas and the charge are countercurrently moved, and the charge is heated at 900-1050℃, not exceeding 1150℃, and the ilmenite is reduced to a high grade titanium rich material.

Product atlas

Technical Parameters

| model | specification | Designing ability | electric motor | Reducer | weight | ||

| (t/h) | model | power(kw) | model | Speed ratio | (t) | ||

| WY118 | Φ1.18×14 | According to the material | YCT225-4A | 11 | ZS75-8-1 | 112 | 33 |

| WY65 | Φ0.65×11 | According to the material | YCT200-4B | 7.5 | ZS65-8-1 | 112 | 25.3 |

| WY40 | Φ0.4×4.8 | According to the material | YCT200-4A | 5.5 | ZS50-7-1 | 100 | 16 |

| WY120 | Φ1.2×20 | According to the material | YCT225-4A | 11 | ZS75-8-1 | 112 | 48 |

| WY150 | Φ1.5×28 | According to the material | YCT225-4B | 15 | ZS95-9-1 | 125 | 68 |

Keyword:

合作案例

Message