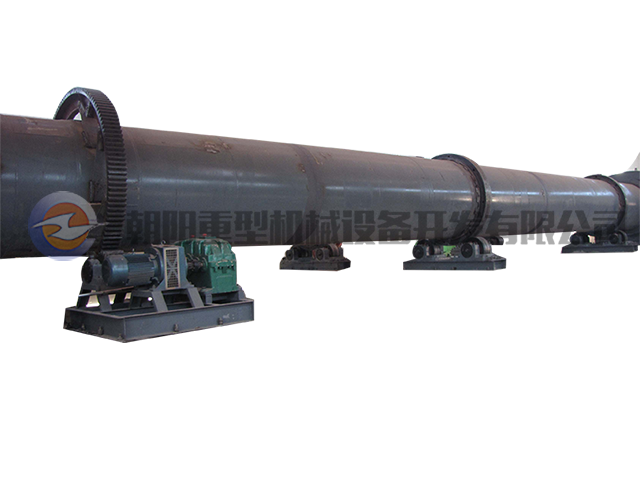

Internal heating rotary kiln

Category:

Rotary Kiln Equipment

产品详情

product description

In the metallurgical industry, rotary kiln can be divided into internal heating rotary kiln and external heating rotary kiln according to different heating methods. The material of the internal heating rotary kiln is in direct contact with the flame and the flue gas, and the oxidizing or reducing atmosphere in the furnace can be realized by adjusting, and the refractory brick is built on the inner wall of the cylinder, and the head and tail lining is lining for high-strength wear-resistant castable, head and tail cover and cylinder The body is a flexible seal that completely eliminates dust and material leakage. Multiple gears can be used to make the cylinder length up to 60 meters and the maximum operating temperature up to 1600 °C. The output is large, and the applicable fuels are liquefied gas, natural gas, coal gas, fuel oil, coal powder, coal, and the like.

Technical performance and characteristics

|

Automatic control

|

|

working principle

The internal heating rotary kiln plays a major role in some ferrous and non-ferrous metals. This equipment is used for heat treatment of ore, concentrate and intermediate products by sintering and roasting. Direct coal, flue gas, gas or natural gas is used as a heat source to oxidize and roast the material in the rotary kiln, and chemical changes occur to produce materials that meet the requirements.

Product atlas

Technical Parameters

| model | specification | Designing ability | electric motor | Reducer | weight | ||

| (t/h) | model | power(kw) | model | Speed ratio | (t) | ||

| NY16 | Φ1.6×20 | 0.3 | YCT250-4A | 18.5 | ZS110-7 | 97.46 | 40 |

| NY18 | Φ1.8×24 | 0.4 | YCT225-4B | 22 | ZSY315 | 100 | 45 |

| NY18A | Φ1.8×28 | 0.45 | YCT225-4B | 22 | ZSY315 | 100 | 52 |

| NY25 | Φ2.5×40 | 3-6 | YCT250-4A | 55 | ZS125 | 63.1 | 145 |

| NY26 | Φ2.6×40 | 10 | YCT250-4A | 75 | ZS145 | 49.63 | 165 |

| NY28 | Φ2.8×44 | 15 | YCT250-4A | 55 | ZS145 | 49.63 | 195 |

Keyword:

合作案例

Message