Pressure straightener

Category:

Straightening Equipment

产品详情

Product Introduction

The pressure straightening machine is also the simplest straightening equipment that uses repeated bending and gradually reduces the bending deflection to achieve straightening purposes. The pressure straightening machine uses a crank connecting rod mechanism or a hydraulically driven movable head to produce a complete reversal of the workpiece and straighten the workpiece. Generally used for straightening large steel beams, rails, and large diameter steel pipes, or as a supplementary straightening for roller straighteners. Pressure straighteners have two structures, vertical and horizontal. The pressure straighteners produced by our company can achieve online detection and intelligent control.

working principle

The working principle of a pressure straightener is to support a workpiece with an original bend between two movable fulcrums of the workbench and align it with the most curved part with a press head for reverse bending. When the bending amount is equal to the workpiece springback amount, the bending part of the workpiece becomes straight after the indenter is withdrawn. In this way, all bending parts of the workpiece must be straightened to achieve the purpose of straightening.

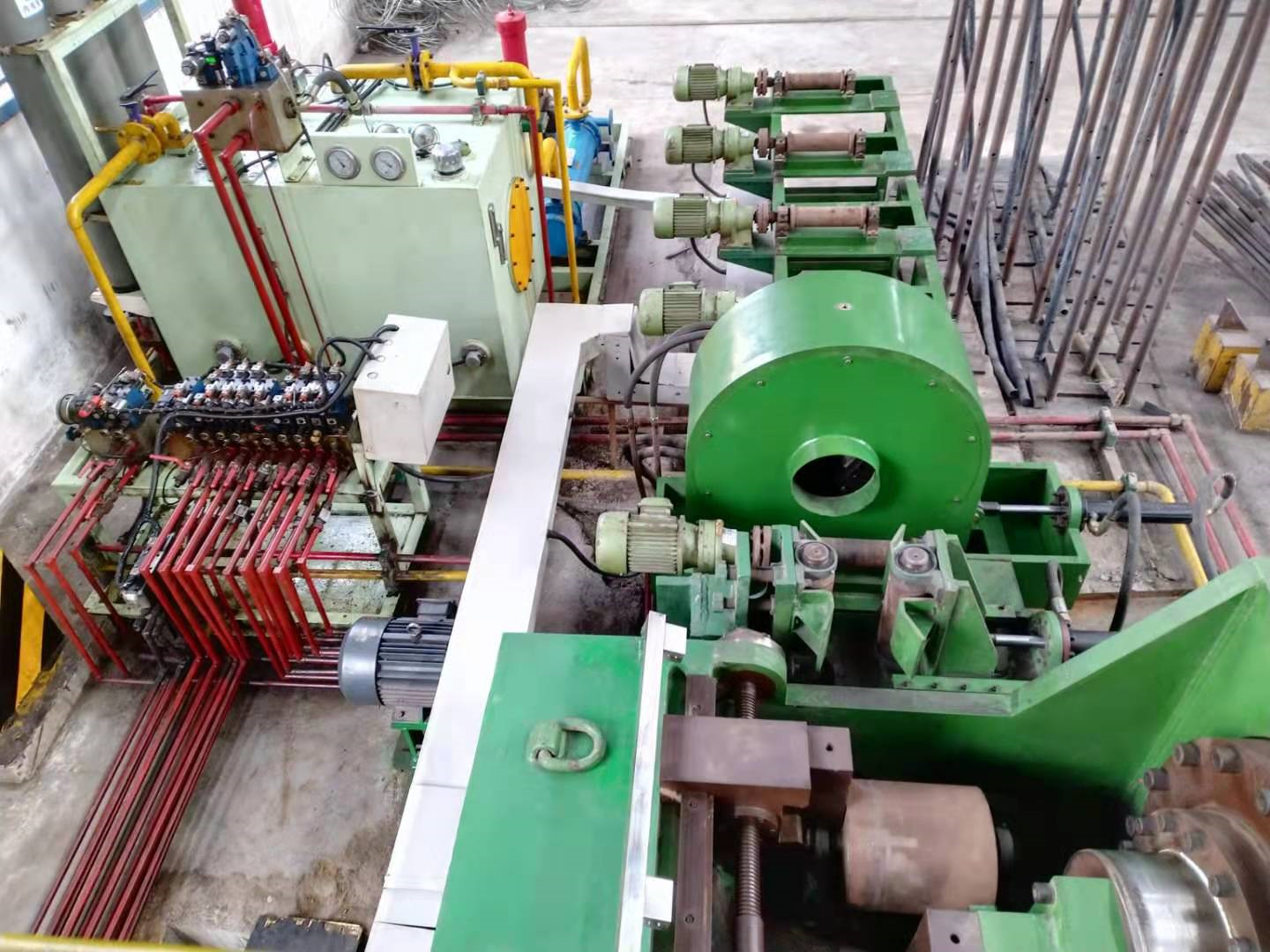

Product Atlas

technical parameter

| order number | model | Head pressure | Straightening material | Straightening speed | Straightening accuracy | remarks |

| 1 | CZYJ-1 | 1MN | metal | Stepless speed regulation | ≤1‰ | Detection device (optional) |

| 2 | CZYJ-3 | 3MN | metal | Stepless speed regulation | ≤1‰ | Detection device (optional) |

| 3 | CZYJ-5 | 5MN | metal | Stepless speed regulation | ≤1‰ | Detection device (optional) |

| 4 | CZYJ-10 | 10MN | metal | Stepless speed regulation | ≤1‰ | Detection device (optional) |

| 5 | CZYJ-15 | 15MN | metal | Stepless speed regulation | ≤1‰ | Detection device (optional) |

Keyword:

prev

prev

合作案例

undefined

Message