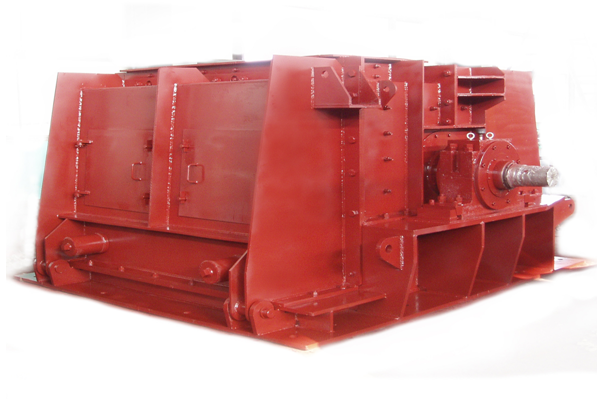

Hammer crusher

Published:

2023-03-07 08:59

Source:

Main uses of hammer crusher

This type of hammer crusher is a model specially designed by our factory technicians according to the characteristics and crushing requirements of active lime (quicklime). Through several years of practical use and user feedback for many times to improve to reach today's ideal usability, that is, the proportion of fine material is large, less than 3mm material accounts for more than 95%, high output, 18-24 tons per hour, the model structure is reasonable, low equipment failure rate. In addition, the hammer crusher can not only be used in the crushing production line, sand production line, but also can replace the cone crusher in the dressing production line. The main working part of hammer crusher is the rotor with hammer (also known as hammer head). The rotor consists of a spindle, a disc, a pin shaft and a hammer. The motor drives the rotor to rotate at high speed in the crushing chamber. The material is fed into the machine from the upper feeding port, and crushed by the hammer of high-speed movement, impact, shear and grinding. In the lower part of the rotor, is provided with a sieve plate, crushed material smaller than the size of the sieve through the sieve plate discharge, larger than the size of the sieve and the coarse grain and resistance to remain in the sieve plate continue to be hit by the hammer and grinding, finally through the sieve plate discharge machine.

Two. Hammer crusher working principle

The motor drives the rotor to rotate at high speed in the crushing chamber. The material is fed into the machine from the upper feeding port, and crushed by the hammer of high-speed movement, impact, shear and grinding. In the lower part of the rotor, is provided with a screen plate, crushed material smaller than the size of the sieve through the sieve plate discharge, larger than the size of the sieve size of the coarse grained resistance to remain in the sieve plate continue to be hit by the hammer and grinding, finally through the sieve plate discharge machine.

Three. Hammer crusher characteristics

(1) Working hammer, casting by new process, with wear resistance and impact resistance.

(2) According to customer requirements, adjust the required granularity.

(3) The overall design is beautiful, compact structure, less wearing parts, convenient maintenance and other advantages, is an upgrade product.

Four. Hammer crusher structure

Hammer crusher is mainly composed of box, rotor, hammer head, counter lining plate, sieve plate and so on.

(1) box body

Mainly made of Q235-A plate welded

(2) Rotor

By the shaft, disc, hammer, pulley and other assembly.

Hammer material: ZGMn13Cr2

(3) counter lining plate

Material: ZGMn13

(4) sieve plate

Material: ZGMn13

Five. Lubrication of machinery

The lubricating part of the body is each bearing, and the bearing seat is provided with an oil cup. It is recommended to use GB7324-87 general lithium grease No. 1 or No. 2. The oil filling amount of the bearing shall be beneficial to ensure that the bearing cavity is filled with 1/2-1/3 oil.

Disadvantages of hammer crusher

The disadvantage of hammer crusher is that the hammer head and lining plate wear extremely serious, short life, so the subject of hammer crusher is how to improve the life of the hammer head and lining plate!

next page

Related News

As late summer gives way to early autumn, the skies are high and the clouds are light—perfect timing for team-building activities. To enrich employees' leisure and cultural lives, strengthen team cohesion and unity, and reignite their enthusiasm for work, Chaoyang Heavy Machinery Equipment Development Co., Ltd. organized a picturesque outdoor team-building event this Friday at the scenic Linglong Mountain Villa in Chaoyang, themed "Forging Team Spirit, Uniting Hearts and Energies."